Each tank is equipped with a calibration table certified by the Customs Agency and an electronic radar level-measuring system which transmits data directly to the control room.

Management and control systems are carried out remotely via PLC.

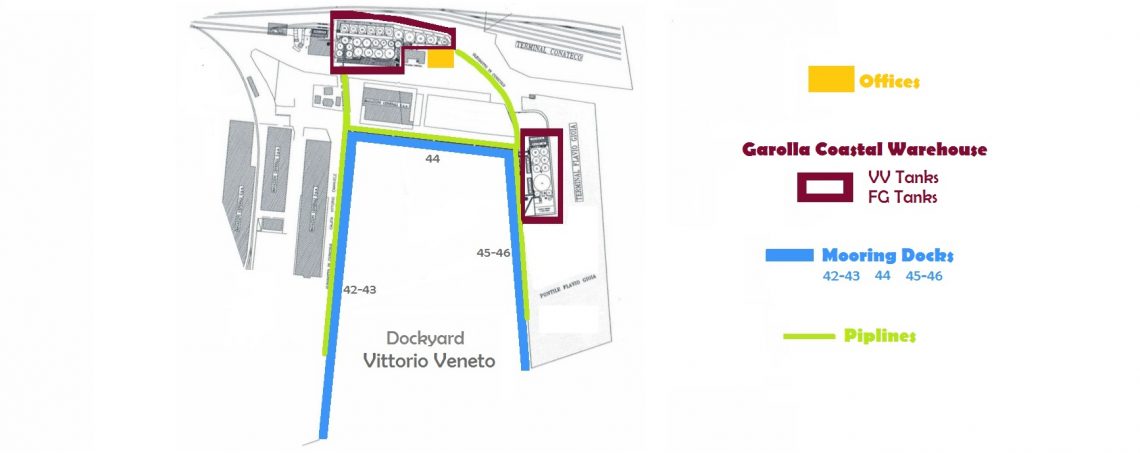

Our warehouse currently consists of 39 metal closed-top tanks above ground, located as shown in the following ground plan:

The storage tanks have been made in accordance with current regulations. Access to the tops is by means of elevator and steel ladders. All tanks are connected to each other by appropriate walkways.

Coastal Storage has the following facilities:

- stainless steel 6 ” pipelines connecting warehouse and mooring docks

- loading platforms equipped with 7 transfer points for loading tanker trucks

- loading area for railway tanks near the port railway link

- 7 electronic tanker truck weighing systems

- 3 control rooms equipped with computerized PLC system for storage management under both normal operating conditions and in case of emergency

- removable generator

- 3 hot water boilers and 2 steam generators – fuelled by mainline gas- for heating up some of the products in storage

- Administrative, Accounting and Operations Office for the issuance of transportation documents

- 2 water/foam fire prevention systems

- closed-circuit video surveillance system

- anti-pollution floating barriers

- skimmer for the recovery of surface oils

In addition, Coastal Storage is equipped with:

- containment basins with stair access and footbridges built on top of retention walls

- safety equipment and fire protection systems

- electric pumps for loading tanker truck and rail tankers

All systems and electrical equipment are in accordance with legal standards.

TANK PROTECTION SYSTEMS

The insides of the tanks have a foam fire prevention system as well as

- Measuring and alarm systems

All tanks are equipped with a level measurement device, temperature measurement device, density metre and with high and very high level alarms, respectively regulated at 80% and 85% of the effective capacity. Data are transmitted to the control room.

- Cooling systems and foam fire prevention system in tanks

The fire prevention system consists of

- 3 pumps – each one acting as a backup to the other – from 308 m³ / h (5,133 lt / 1 ‘)

- 1 electric pump

- Hydrants for more than 300 cubic metres, from the port mainline water supply

- 2 premix fluid displacement generators with 2,000 litre capacity tank of foam

Each tank is equipped with foam fire prevention device and two cooling loops.

In the event of an emergency it is also possible to fill the tanks of the fire water supply with seawater.